Overview

Requirement Assessment:

The cost of plastic injection mold design and development is often the highest expense in product development. Chia Kuan evaluates your product's functionality and appearance requirements to provide the most suitable materials and mold processes, including DFM (Design for Manufacturability), sample modeling, and product precision requirements.

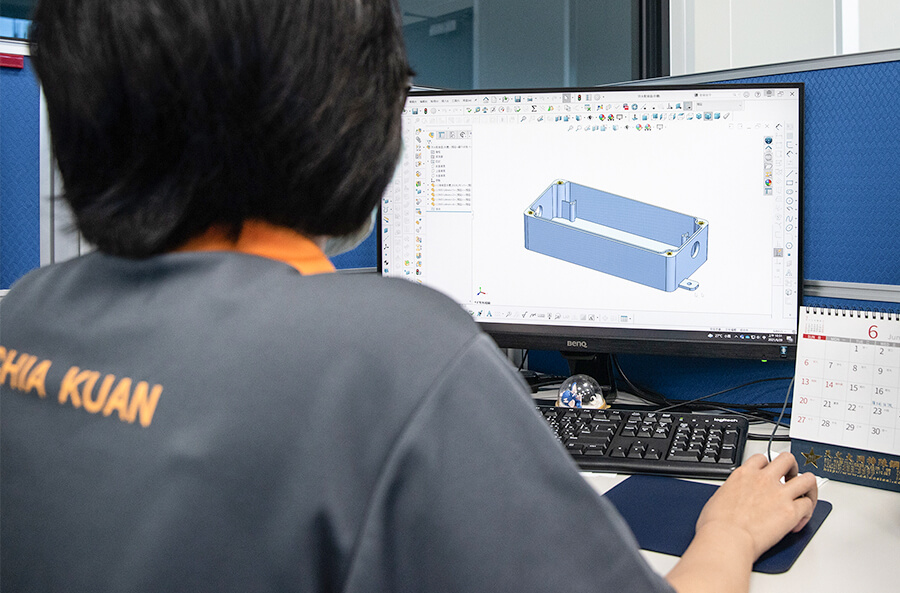

3D Design:

Using customer drawings or samples, Chia Kuan offers diversified mold manufacturing services with the help of professional software and equipment, such as Dassault Systèmes SOLIDWORKS Standard & Plastics Professional and Autodesk Product Design & Manufacturing Collection.

Production Planning:

We create the most suitable production schedule to meet client expectations on delivery time and quantity.

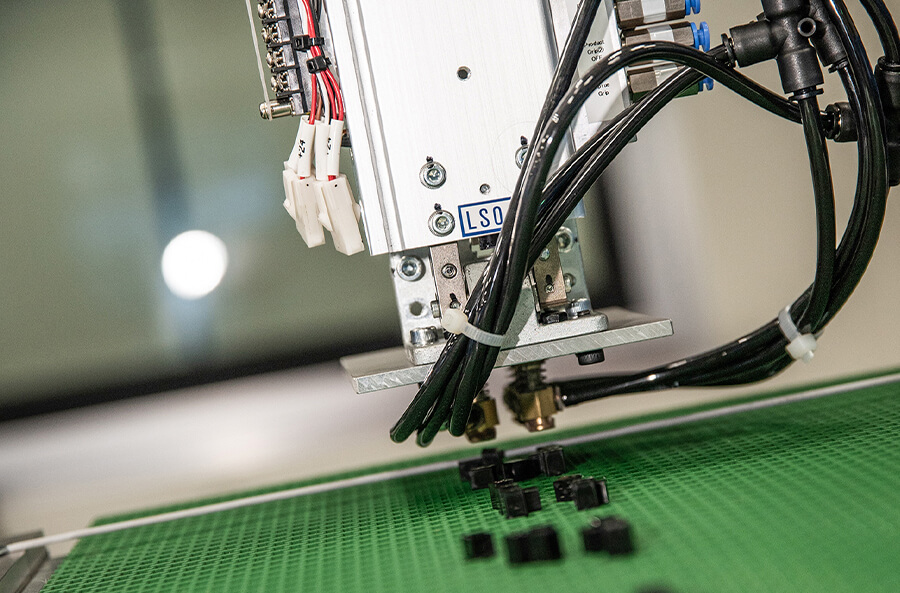

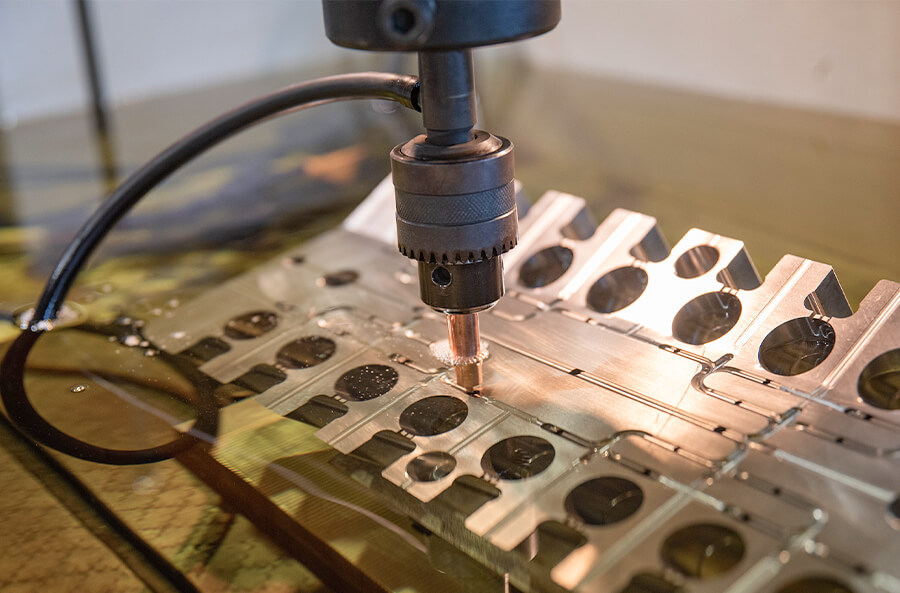

Mold Manufacturing:

With over 36 years of professional experience, Chia Kuan effectively reduces the number of trial runs needed, shortens mold development cycles, and lowers manufacturing costs while producing molds that meet real-world application requirements.

Quality Control:

We emphasize precision in our products and thoroughly inspect all production samples to ensure high-quality results in mass production.

Production & Delivery:

Once the sample is approved by the client, we proceed with mass production at consistent quality levels and deliver the final product according to the agreed timeline.

037-582967

037-582967